Ecoclean je lídrem změny: globální poskytovatel lokálních řešení

Svět se rychle mění a je poháněn megatrendy, jako je automatizace, udržitelnost a bezpečnost, které vyžadují přizpůsobení - od našich zákazníků, a tedy i od nás. Jako jeden z předních světových poskytovatelů řešení pro čištění průmyslových komponent, povrchovou úpravu a automatizaci se skupina SBS Ecoclean Group staví k těmto výzvám čelem a proaktivně a s ohledem na budoucnost se snaží o diverzifikaci. Náš přístup spočívá v tom, že se díváme na to, co náš "box nástrojů a odborných znalostí" nabízí, a dovedně je kombinujeme, abychom vytvořili zcela nové systémy, které nejlépe vyhovují novým standardům a potřebám. Tento způsob myšlení nám pomáhá přemýšlet v kategoriích řešení, nikoliv pouze produktů. Abychom udrželi krok s náročnými požadavky trhu, rozšířili jsme letos dále naše portfolio a vyvinuli specializovaná řešení pro high-tech odvětví, jako je MedTech, High Purity, pro nové výzvy v oblasti letectví a mobility, a dosáhli jsme významného pokroku v oblasti ekologického vodíku tím, že jsme zahájili sériovou výrobu našich decentralizovaných elektrolyzérů.

Společnost Ecoclean má v odvětví MedTech obzvláště silnou pozici díky komplexní nabídce, která pokrývá všechny fáze čištění komponent - od předčištění a mezikroků až po konečné čištění a pasivaci - a to vše z jediného zdroje. Navíc jsme flexibilní a dokážeme naše technologie přizpůsobit specifickým potřebám každého zákazníka a globálnímu regionu. S novou rozsáhlou řadou produktů vytvořenou pro MedTech pokrýváme i požadavky dalších průmyslových odvětví, jako jsou hodinářství a šperkařství a vysoce čistá / přesná optika.

Naše globální přítomnost a místní partnerství nám dávají výhodu, že můžeme přímo reagovat na potřeby na místě a posilovat své postavení v klíčových regionech, přičemž máme k dispozici globální infrastrukturu zdrojů, služeb a sdílení know-how. V roce 2024 jsme dále posílili naši globální působnost rozšířením na více míst, což nám umožňuje vyrábět řešení na místní úrovni a přizpůsobovat je přesně místním požadavkům. Do nového roku 2025 vstupujeme jako solidní "globální poskytovatel lokálních řešení" pro naše zákazníky.

Vzhledem k tomu, že se svět neustále mění, budeme i nadále rozšiřovat naše portfolio a globální působnost, abychom uspokojili potřeby tam, kde vznikají. Se sítí nejmodernějších technologií a odborných znalostí za zády hledíme do budoucnosti pozitivně a odhodlaně!

Posílení naší globální přítomnosti s místními odbornými znalostmi

Vzhledem k dynamickým podmínkám na trhu a rostoucí poptávce po inovativních řešeních pro nás nikdy nebylo důležitější identifikovat další klíčové regiony, kde můžeme nejlépe poskytovat služby našim zákazníkům, a vytvořit silnou globální přítomnost. Stát se regionálním expertem je nezbytné pro poskytování komplexních balíčků řešení na klíč a služeb, které rezonují s místními trhy a splňují potřeby zákazníků.

Strategické partnerství se společností JKS Engineering v Malajsii

V tomto duchu naše skupina otevřela novou kapitolu v asijsko-pacifickém regionu, když naše společnost Ecoclean GmbH získala menšinový podíl v malajské společnosti JKS Engineering (M) Sdn Bhd, která se specializuje na čištění dílů, povrchovou úpravu a automatizační řešení. Od zahájení partnerství v srpnu 2024 učinila společnost Ecoclean významný krok vpřed v posilování své přítomnosti na trhu a schopností poskytovat služby zákazníkům v regionu.

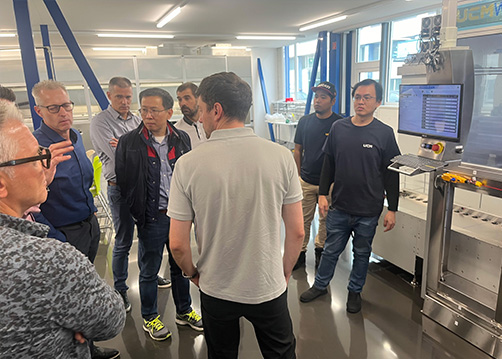

Klíčovým úspěchem této spolupráce je uvedení systému UCMBaseLine na místní trh, který je přizpůsoben pro malajský a širší jihoasijský trh. Kolegové z deseti zemí se nedávno sešli ve švýcarském Rheinecku na školení o základních aplikacích systému, kde tým JKS prokázal své odborné znalosti a místní vědomosti.

Ecoclean Czech nabízí novou flexibilitu

Naše česká dceřiná společnost rozšiřuje své výrobní kapacity, aby mohla uvést na trh kompletní novou řadu produktů EcoCompact, která bude k dispozici ve třech různých velikostech. V roce 2023 jsme rozšířili výrobní sortiment společnosti Ecoclean Czech a představili jsme EcoCcompact L, nového člena rodiny jednokomorových čisticích systémů EcoCcompact pro čištění a konzervaci průmyslových dílů. Do konce roku 2024 bude následovat model EcoCcompact XL. Toto rozšíření naší produktové řady a mezipodniková spolupráce mezi naším kompetenčním centrem Ecoclean ve Filderstadtu a sesterskou společností v České republice je dalším krokem k tomu, abychom našim zákazníkům poskytli ještě větší výběr a flexibilitu, jakož i nákladově efektivní řešení pro jejich specifické čisticí úkoly.

Ecoclean Czech se bude ještě více specializovat na výrobu automatizovaných dopravníkových systémů naší skupiny pro nakládání a vykládání strojů na čištění průmyslových dílů. Specializované dopravníkové technologie vyráběné v České republice pro automatizaci procesu nakládky a vykládky - včetně přesunu do další fáze procesu - zefektivní celý proces kolem čištění dílů.

Posílení naší přítomnosti ve Španělsku a Portugalsku

Aby společnost Ecoclean uspokojila rostoucí poptávku španělských a portugalských zákazníků, rozšířila svůj prodejní tým na Pyrenejském poloostrově. Noví kolegové ve společnosti Ecoclean France, kteří se věnují výhradně tomuto regionu, zjišťují nové potřeby místního trhu, nové aplikace a potenciální projekty, které se na těchto trzích rozvíjí. Nový tým má nejen důkladnou znalost iberského trhu, ale také plynně hovoří jazyky tohoto regionu, což nám umožňuje ještě rychleji a efektivněji reagovat na dotazy zákazníků a poskytovat nejnovější technologie v oblasti čištění!

Více informací

Chcete-li se dozvědět více o našem místním zastoupení, obraťte se na:

- Ecoclean v jihovýchodní Asii: info.monschau(at)ecoclean-group.net

- Ecoclean v České republice: info.czechia(at)ecoclean-group.net

- Ecoclean v regionu Iberie: info.france(at)ecoclean-group.net

High-Purity: Průmyslové čištění nové úrovně

Požadavky na průmyslové čištění nebyly nikdy tak rozmanité, protože se objevují nové výrobky, složité geometrie dílů a různé materiály a velikosti. Společnost Ecoclean poskytuje inovativní a udržitelná řešení pro efektivní a vysoce kvalitní čištění v celém výrobním řetězci - a právě vývoj a evoluce těchto inovací definovaly náš rok 2024.

Modulární řešení pro čištění s vysokou čistotou na míru

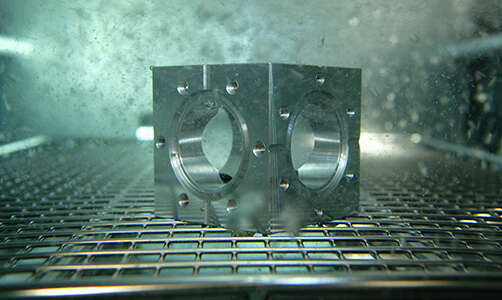

Různorodost úkolů čištění s vysokou čistotou vyžaduje přizpůsobivá čisticí řešení a flexibilní sortiment výrobků. Jako dodavatel kompletního sortimentu máme odpověď: inovativní modulární systémy. Konkrétně inovativní modulární dávkové čisticí systémy EcoCvela pro čištění na bázi vody a EcoCstretch pro čištění rozpouštědly nebo modifikovaným alkoholem. Oba systémy lze vybavit různými volitelnými doplňky a dalšími funkcemi, které poskytují individuální řešení pro různé úkoly čištění součástí.

Přesné čištění pro průmysl MedTech a hodinářský průmysl

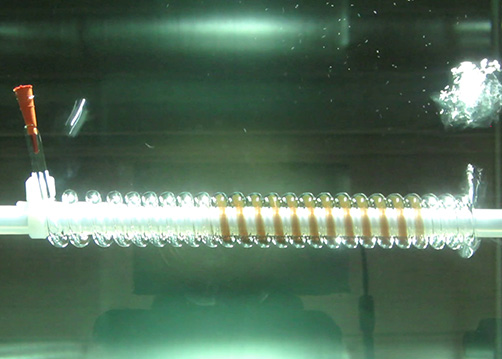

Ve zdravotnictví a hodinářství se již tak vysoké nároky na čistotu stále zvyšují. Společnost Ecoclean na to reaguje pokročilými ultrazvukovými imerzními systémy pro finální čištění a pasivaci. Rozšířili jsme naši průkopnickou technologii čištění pulzním tlakem (PPC): Společnost Ecoclean pochopila jedinečné výzvy lékařského a hodinářského průmyslu a vyvinula proces pasivace pulzním tlakem (PPP). Nyní nabízíme technologii, která na povrchy nanáší ochranný povlak, přičemž změny tlaku v procesní komoře umožňují, aby se pasivace dostala do všech dutin a otvorů. Na čisticí a pasivační procesy PPC a PPP vyvinuté společností Ecoclean jsme podali patentové přihlášky!

Průkopnické inteligentní technologie pro udržitelné průmyslové čištění

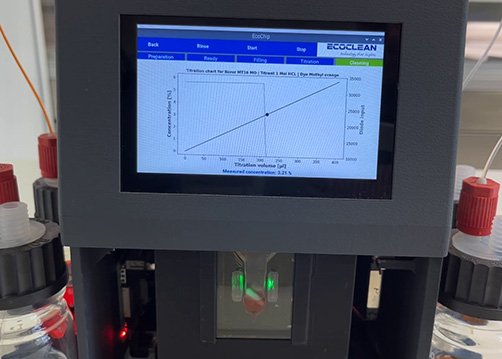

Další připravovanou inovací je technologie Smart Drying. Tato funkce, vyvinutá ve spolupráci našich dvou kompetenčních center, využívá senzor vlhkosti pro systémy s vodní komorou k optimalizaci doby sušení a jejím cílem je snížit spotřebu energie přibližně o 10 %. A pokud jde o nové vymezení hranic průmyslového čištění dílů, naše technologie lab-on-a-chip rovněž umožňuje ekologický přístup: Mobilní, samostatný přístroj určuje koncentraci čisticích prostředků titrací, což zákazníkům umožňuje získat přesné informace z každé čisticí lázně s využitím minima odebraných čisticích prostředků.

Dalším průlomem je rozšíření našeho pokročilého řešení pro měření akustického výkonu (APM) o detekci vysokofrekvenčního ultrazvuku až do dvou megahertzů pro velmi jemné čištění citlivých povrchů. Stroje nejen dodáváme a vyvíjíme, ale také pravidelně komplexně sledujeme jejich výkonnost, abychom se mohli neustále zlepšovat. A dalším krokem je spojit všechny tyto technologie do jednoho monitorovacího softwaru a využít umělou inteligenci k zefektivnění používání strojů a usnadnění života našich zákazníků.

Více informací

Vyzkoušejte si nejmodernější technologii čištění dílů naživo:

- Modulární řešení dávkového čištění s EcoCvela a EcoCstretch v našem testovacím centru vysoké čistoty v Dettingenu: info.filderstadt(at)ecoclean-group.net

- Technologie pulzního tlakového čištění (PPC) a pulzní tlakové pasivace (PPP), stejně jako senzor vlhkosti, lab-on-a-chip & měření akustického výkonu (APM) v našem testovacím centru pro přesné čištění a medotechniku v Monschau: info.monschau(at)ecoclean-group.net

EcoLyzer: průkopník zelené vodíkové budoucnosti

Zelený vodík, vyráběný udržitelným způsobem elektrolýzou vody, je klíčovým faktorem energetického přechodu. S rostoucí dostupností vodíku se tato čistá technologie stane životaschopnou alternativou k fosilním palivům, zejména v energetice a dopravě.

Po třech letech usilovného vývoje byl letos na jaře EcoLyzer P200 uveden do sériové výroby po úspěšném dokončení testovacích fází projektu "EcoLyzerBW", který byl financován ve spolupráci s Centrem pro výzkum solární energie a vodíku v Bádensku-Württembersku (ZSW) v Německu.

Partner při každém kroku k udržitelnosti

Náš EcoLyzer podporuje místní ekologickou výrobu vodíku pomocí robustního elektrolyzéru s nízkými nároky na údržbu, jenž je celosvětově dostupný od společnosti Ecoclean. Lze jej škálovat jako samostatnou jednotku nebo realizovat jako systém na klíč s výkonem od 1 do 20 MW, díky čemuž je přizpůsobitelný různým potřebám, od CO2 neutrální mobility až po skladování energie z obnovitelných zdrojů. Poskytováním decentralizovaných vodíkových řešení umožňujeme společnostem dosáhnout jejich cílů v oblasti udržitelnosti.

A samozřejmě stojíme po boku našich zákazníků jako důvěryhodný partner: Ecoclean se zavazuje podporovat své zákazníky a poskytovat jim poradenství po celý životní cyklus projektu. Jako systémový integrátor nabízíme odborné znalosti od technologického poradenství až po implementaci a provoz našeho systému EcoLyzer.

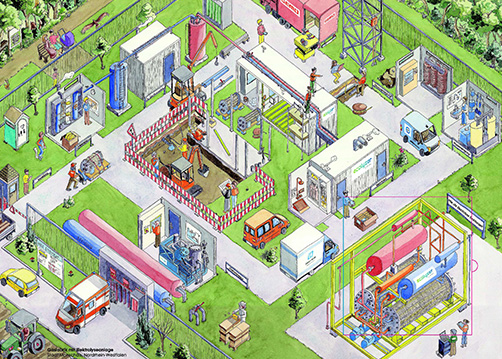

Sdílení znalostí: elektrolýza vysvětlená zábavnou formou

Náš EcoLyzer je součástí nové knihy Hidden Object (Skryté objekty) ilustrátorky a nakladatelky Biancy Brinnerové. Pro nás jako strojní inženýry to byla neobvyklá, ale současně velmi zajímavá žádost být součástí tohoto speciálního projektu, který vysvětluje složité technologie vzrušujícím a srozumitelným způsobem. Společně s Andreasem Brinnerem, bývalým zaměstnancem Centra pro výzkum solární energie a vodíku v Bádensku-Württembersku (ZSW), vytvořila ilustrátorka a vydavatelka knihu skrytých objektů, která vysvětluje, jak se vodík vyrábí a používá - na příkladu našeho EcoLyzeru.

Kniha, která byla oficiálně představena na mezinárodním knižním veletrhu ve Frankfurtu nad Mohanem v říjnu 2024, má pomoci mladým, ale i starším lépe porozumět tématu vodíku.

Jsme hrdí na to, že se můžeme podílet na tomto důležitém vzdělávacím projektu.

Více informací

- Další informace o programu EcoLyzer.

- Chcete-li kontaktovat tým EcoLyzer v našem kompetenčním centru v Monschau, obraťte se na adresu info(at)ecolyzer.com

Místní pro místní: zprávy z Indie a Číny

V roce 2024 skupina SBS Ecoclean posílila svůj závazek vůči místním trhům v souladu se svými hlavními ambicemi: přizpůsobovat se změnám na trhu, uspokojovat potřeby zákazníků a poskytovat řešení s úzkou a spolehlivou podporou. Společně tím plní nejen potřeby trhu na místní úrovni, ale předvídá je.

Indie: synergií k posílení

V Indii učinila společnost Ecoclean významný krok sloučením společnosti Mhitraa Engineering Equipments Pvt. Ltd. se společností Ecoclean Machines Pvt. Ltd., čímž spojila své odborné znalosti a zdroje, aby mohla efektivněji a v širším měřítku poskytovat služby zákazníkům. Díky této fúzi nyní nabízíme kromě dávkového čištění také pokročilé robotické a dopravníkové stroje, jako jsou EcoCtram a EcoCrapid, což nám umožňuje rozšířit naše portfolio výrobků a nabídnout nová, přesná řešení šitá na míru požadavkům zákazníků. Tato posílená nabídka - z Pune do PAN Indie - zahrnuje také komplexní služby v oblasti retoolingu v rámci společnosti Mhitraa Retooling, za kterou stojí tým vysoce kvalifikovaných pracovníků v oblasti dávkového čištění, čištění vodou a rozpouštědly a robotických systémů.

Nově otevřený závod v Pune navíc nabízí větší výrobní plochu, nejmodernější technologické centrum a špičkovou laboratoř s podmínkami čistých prostor.

Aby společnost Ecoclean India mohla dále reagovat na místní poptávku pomocí místních řešení, zaměřila se také na odvětví MedTech a Optics. A první výsledky jsou viditelné - s první místní objednávkou z odvětví MedTech na generální čištění implantátů reaguje naše dceřiná společnost v Indii na regionální poptávku specializovanými řešeními a odbornými znalostmi. Společnost Ecoclean India také aktivně zkoumá místní příležitosti v segmentu optiky a zajišťuje, aby naše pokročilé čisticí technologie a znalosti specifické pro dané odvětví odpovídaly vyvíjejícím se potřebám indického trhu.

Čína: zavádění technologie VOC

V Číně je náš výzkumný a vývojový tým v Šanghaji průkopníkem nových způsobů snižování těkavých organických látek (VOC) prostřednictvím inovativní technologie následného zpracování. Toto řešení, vyvinuté ve spolupráci s naším kompetenčním centrem v německém Filderstadtu, využívá VUV (vakuové ultrafialové) lampy v reakční komoře, které vystavují výfukový vzduch UV záření, čímž dosahují částečné nebo úplné degradace těkavých organických látek. Tato technologie doplňuje stávající systémy vyhovující požadavkům na VOC a je slibným krokem k menší ekologické stopě. Tato inovace, na kterou je podána patentová přihláška, je důkazem našeho závazku k udržitelným technologiím, které jsou prospěšné jak pro zákazníky, tak pro životní prostředí.

Více informací

Chcete-li kontaktovat naše pobočky, obraťte se na

Společnost Ecoclean reaguje na potřeby amerických zákazníků a podniká další kroky v oblasti zdravotnické technologie a systémů pro místní trh.

V roce 2024 se společnost Ecoclean zaměřila na navazování nových partnerství a rozšiřování svého portfolia výrobků, aby přesně odpovídalo potřebám amerického trhu. V odvětví MedTech jsme položili základní kámen pro „MedTech Clean&Pack Solutions by Ecoclean and EnPak “ - nové centrum MedTech Cleaning Solutions v návaznosti na náš jasný závazek poskytovat nejmodernější stroje a řešení velkým výrobcům a také rozšířit logistické řetězce pro specializované dodavatele MedTech o smluvní čisticí služby. Navíc díky rozšířené produktové řadě našeho systému EcoCcompact budeme nabízet flexibilní bezemisní čisticí systém ve třech velikostech, který pokryje potřebu špičkového a nákladově efektivního řešení.

Strategické partnerství ve Warsaw, Indiana

Společnost Ecoclean uzavřela klíčové partnerství s firmou EnPak LLC ve Warsaw ve státě Indiana, v srdci amerického odvětví MedTech, v blízkosti výrobců zdravotnických prostředků. V závodě společnosti EnPak o rozloze 11 000 čtverečních stop budujeme „MedTech Clean&Pack Solutions by Ecoclean and EnPak “, který bude otevřen na začátku roku 2025. Centrum bude vybaveno systémem jednokomorového předčištění s využitím vakuové technologie. Pro finální čištění budeme používat náš ultrazvukový vícestupňový čisticí systém - UCMSmartLine. Partnerství se společností EnPak nám umožní nabízet další služby v oblasti balení, kontroly řízení zásob, plnění objednávek a validace - vše v souladu s předpisy FDA a MDR.

„MedTech Clean&Pack Solutions by Ecoclean and EnPak “ ve Warsaw bude sloužit předním výrobcům zdravotnických prostředků a společnostem, které tyto výrobce OEM podporují specializovanými komponenty nebo službami.

Smluvní čištění pro výrobce zdravotnických prostředků

Protože jsme si vědomi místních potřeb a zájmů našich zákazníků, budeme v tomto novém zařízení ve Warsaw nabízet kromě čisticích řešení MedTech Cleaning Solutions také smluvní čištění. Smluvní čištění je atraktivní možností pro společnosti, které vyrábí pouze příležitostně nebo v malých sériích. Smluvní čištění navíc nabízí vysokou míru flexibility, protože výrobci mohou rychle a snadno přizpůsobit objem výroby kolísající poptávce. Jedná se o další krok v rámci řešení společnosti Ecoclean na klíč, která podporují velké výrobce a společnosti na všech úrovních dodavatelského řetězce. A se společností EnPak po našem boku je budoucnost jasná!

Nová řada EcoCompact

Nová řada EcoCompact rozšiřuje naši nabídku produktů a je navržena tak, aby pokryla poptávku po špičkových systémech a cenově výhodných řešeních pro zákazníky. Stroje EcoCcompact - vyráběné společností Ecoclean Czech v Oslavanech - jsou k dispozici ve třech velikostech a reagují na poptávku trhu po provozu s téměř nulovými emisemi při splnění všech požadavků EPA.

Modely EcoCcompact L a XL nabízí větší velikosti dávek, zvýšenou kapacitu oleje a robustní výkon bez předimenzování. Zatímco model L zdvojnásobuje objem koše a hmotnostní kapacitu dávky, model XL obsahuje vyšší destilační a ultrazvukový výkon, což z něj činí přizpůsobivou a nákladově efektivní alternativu k ostatním systémům na trhu.

Více informací

Chcete-li kontaktovat naše americké kolegy, obraťte se na info.usa(at)ecoclean-group.net

![[Translate to Tschechisch:] Newsletter Icon [Translate to Tschechisch:] Newsletter Icon](/fileadmin/Images/ECOCLEAN/06_News/02_Newsletter/ecoclean_newsletter_icon.png)

Nenechte si ujít náš další newsletter

Newsletter Archive

| Dokument | Datum | Název | Jazyk | Download |

|---|

![[Translate to Tschechisch:] Ecoclean solutions](/fileadmin/Images/ECOCLEAN/Newsletter/2024/Website_Introduction_20241104.jpg)